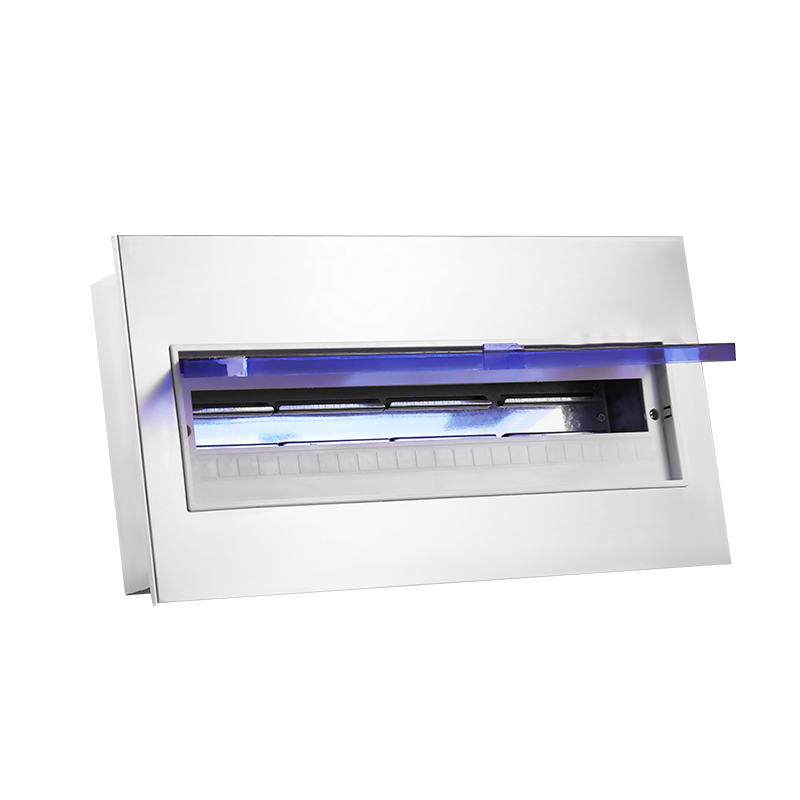

A Distribution Board is a central component in electrical systems that divides incoming power into multiple circuits, while providing protection against overloads, short circuits, and other electrical faults. It is used across residential, commercial, and industrial settings to ensure that power is delivered safely and efficiently. OEM manufacturers often produce these boards to meet specific project or client requirements, offering a variety of configurations, materials, and features.

Distribution Boards are built with several key features to meet safety and functional needs:

| Feature | Purpose |

|---|---|

| Modular design | Makes installation, expansion, and maintenance easier |

| Circuit protection | Prevents electrical faults from affecting other circuits |

| Compact enclosure | Saves space, organizes wiring, and reduces risk of accidental contact |

| Monitoring options | Allows users to check system status and detect faults early |

The design of a Distribution Board depends on its intended environment. In industrial settings, boards often handle high current loads and may be installed in harsh or dusty conditions. In residential and commercial areas, space efficiency, compact design, and ease of use are usually prioritized. Common options include:

- Different types of breakers to match specific circuit requirements

- Custom labeling and color coding for easy identification

- Enclosures made of metal, plastic, or composite materials to suit environmental conditions

Maintenance and reliability are central to the operation of a Distribution Board. Many boards are designed to allow replacement of fuses or circuit breakers without shutting down the entire system. This feature helps reduce downtime and ensures continuous power distribution. Regular inspection, cleaning of dust or debris, and checking connections are part of standard maintenance procedures to prevent system failures.

Some Distribution Boards include monitoring and control features that allow users to track electrical load, detect overloaded circuits, and receive alerts when maintenance is needed. These capabilities are useful in larger facilities or buildings with complex electrical systems, helping facility managers maintain operational efficiency and safety.

Safety is another important aspect of Distribution Board design. Boards often include secure enclosures, organized internal wiring, and clear labeling to minimize the risk of accidents. Proper internal layout ensures that each component is easily accessible for maintenance or replacement, which also supports long-term reliability.

In summary, a Distribution Board is a practical and essential component for organizing and protecting electrical power distribution. Modular design, circuit protection, monitoring options, compact enclosures, and secure installation make it suitable for a wide range of applications. OEM boards are customized to meet specific project needs, helping users manage electrical systems safely and efficiently.

FAQ

Q: What is a Distribution Board?

A device that divides incoming electrical power into separate circuits and protects them from overloads or faults.

Q: What features are included in a Distribution Board?

Common features include modular design, circuit protection, compact enclosures, and monitoring options.

Q: How are Distribution Boards maintained?

Many allow replacement of breakers or fuses without shutting down the system. Regular inspection and cleaning also help maintain safety and reliability.

Q: Where are Distribution Boards used?

They are used in homes, offices, factories, and other facilities to safely manage electrical power distribution.

Q: Why are OEM Distribution Boards used?

OEM boards are customized to meet project-specific requirements, offering flexibility in design, materials, and features for different environments.

English

English русский

русский عربى

عربى